Desktop production of small, high

resolution parts

Introducing the D4K, the highest resolution professional-grade desktop 3D printer. In addition to having the fastest speed for a standard DLP printer, the D4K from ETEC delivers extremely accurate parts with the finest detail available. The D4K is compatible with most ETEC materials, including options suitable for end-use applications, dental, and jewelry.

The D4K Industrial is built on the most

reliable 4K DLP projector and includes ETECs patented PSA assembly for low peel

forces between layers. Brought to you by the original inventors of DLP 3D

printing technology.

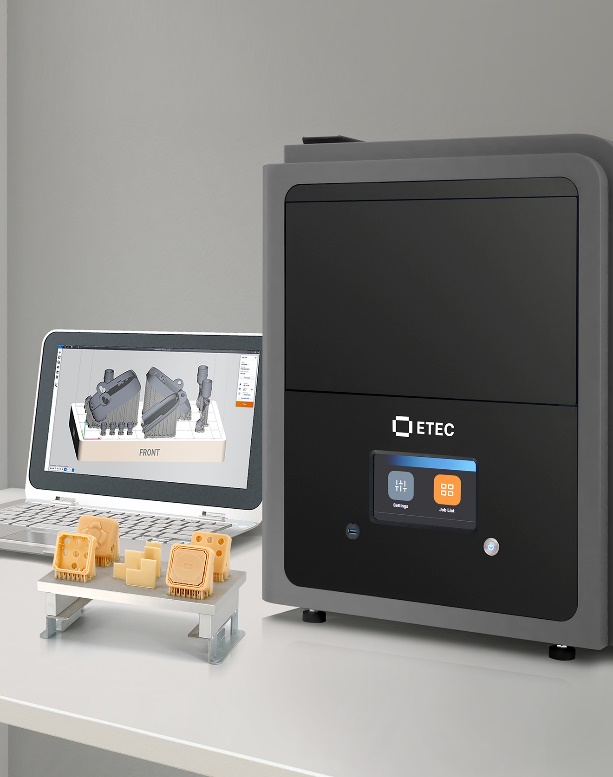

Easy to use

With few moving parts and easy to use

software, the D4K makes it easier than ever to produce high-resolution,

professional-quality parts.

Designed to be an easy to use desktop solution, the D4K makes it easy to set up your print jobs with an easy to use software that optimizes part orientation and support structures to maximize part success and throughput. With the ability to process a plethora of ETEC’s materials, changing material on the D4K is simple, taking less than 2 minutes.

MADE POSSIBLE BY:

Under two-minute material changes

Software-controlled workflow

Affordable industrial-grade printing

Professional-grade 3D printing at one-third the operating cost of comparable systems Users no longer need to compromise between part quality, print speed and affordability. The D4K delivers professional-grade 3D printing at a fraction of the cost of comparable systems, bringing the benefits of additive manufacturing into reach for all designers and engineers.

MADE POSSIBLE BY:

Affordable

Industrial DLP chip

Easy-to-use hardware

Wide Material Compatability

Thanks to the D4K’s industrial DLP chip and high powered 385 nm light source, the printer is capable of efficiently printing a wide variety of materials. No matter what the application is; the D4K can print a material with the required properties. Unlike some competitive resin systems, shelf life of unused material is never a concern as any uncured resin can be easily stored and reused for months, enabling economic material usage.

MADE POSSIBLE BY:

Industrial DLP chip

385 nm wavelength light source

Long material shelf life

|

Featured Materials

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||